H1: How to Select Hair Bows for Private Label and Custom Branding

Hair bows are timeless accessories that blend style, texture, and personality. Whether you’re building a private label line or sourcing for a retail brand, choosing the right hair bow supplier determines your success in terms of quality, cost, and customization. This guide walks you through the essentials of materials, MOQ, and production steps for building your signature bow collection.

🎀 Step 1: Identify Your Target Market

Before diving into production, define your target market clearly. Are you creating kids’ hair bows, luxury satin collections, or everyday fashion lines? Each segment requires a different choice of fabrics, finishing, and embellishments.

For example:

-

Kids’ bows: focus on safety, soft fabrics, and smaller sizes.

-

Fashion bows: emphasize trend colors and premium packaging.

-

Promotional or gift bows: target affordability and quick production cycles.

Clarifying your audience helps your manufacturer select proper materials and plan batch production efficiently.

🎀 Step 2: Choose the Right Fabrics

Fabric quality defines both texture and price. The most common materials for hair bows include:

-

Grosgrain ribbon – durable and structured; ideal for school bows.

-

Satin or silk – shiny and luxurious, suitable for boutique lines.

-

Cotton or linen blends – for casual, eco-friendly styles.

-

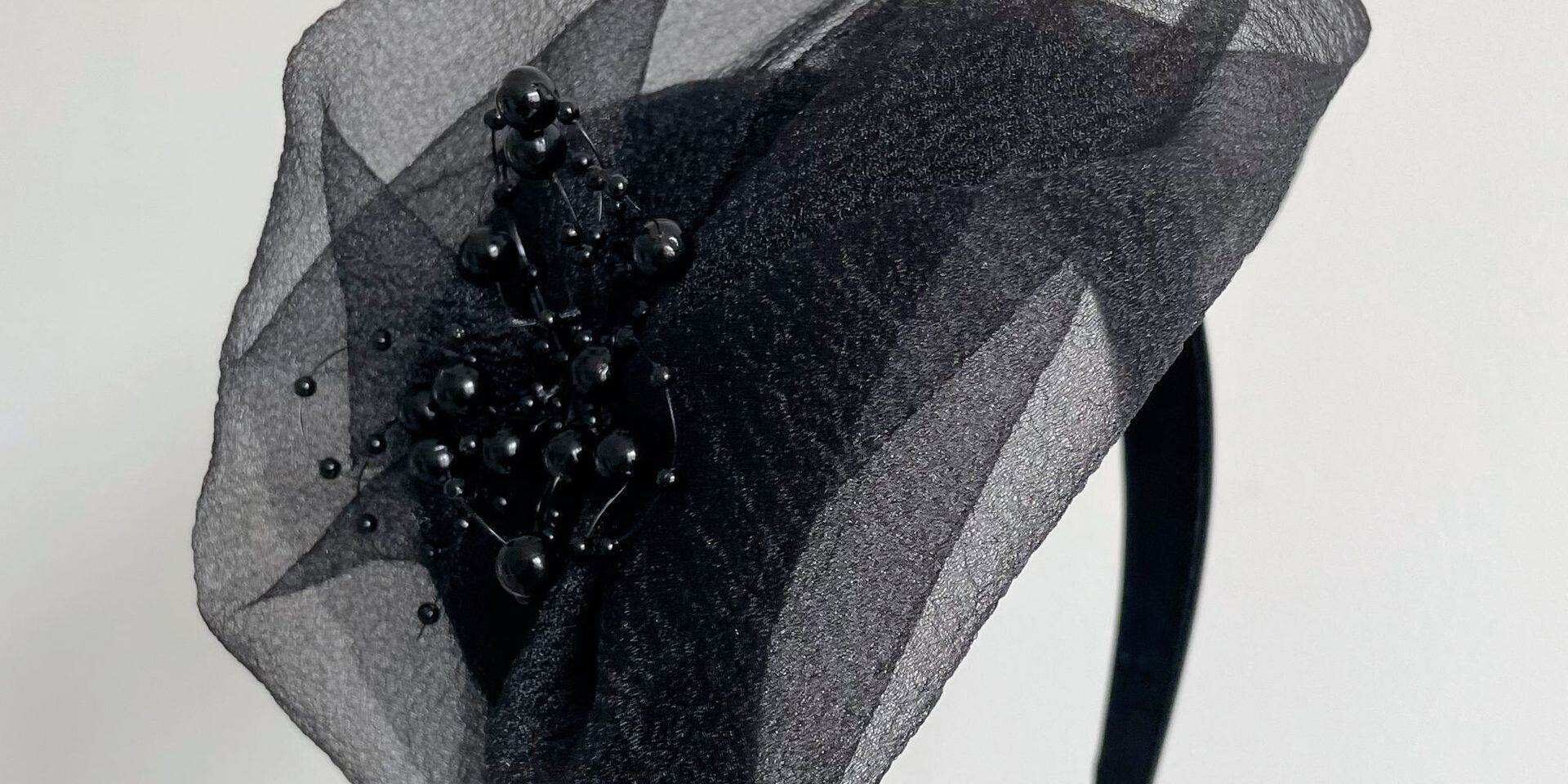

Velvet or organza – premium texture for festive or holiday launches.

Your chosen Hair Accessories Manufacturers can provide swatches and Pantone-matched dyeing services to ensure color consistency across large orders.

🎀 Step 3: Understand MOQ and Sampling

Private label production often starts with MOQ (Minimum Order Quantity). For hair bows, the MOQ typically ranges from 300–500 pieces per color or design.

To test the market before committing to bulk orders, request pre-production samples from your Hair Bow Manufacturers. Sampling helps confirm bow size, ribbon stiffness, clip type, and stitching quality. Once samples are approved, production setup becomes smoother and more predictable.

🎀 Step 4: Branding and Packaging

Private label success depends heavily on branding. Discuss with your supplier about:

-

Logo Application: Printed tags, woven labels, or engraved metal clips.

-

Packaging Styles: PVC boxes, hanging cards, or eco paper wraps.

-

Retail Readiness: Barcode placement and back-card printing.

High-quality packaging can elevate your brand presence and justify a higher retail price. Many factories now offer in-house packaging services, saving you from coordinating multiple vendors.

🎀 Step 5: Quality Control and Compliance

When selling to international markets, compliance and safety testing are essential, especially for children’s bows. Confirm whether your factory follows EN71, REACH, or CPSIA standards.

QC checks should cover:

-

Clip durability (open/close test)

-

Colorfastness under sunlight or washing

-

Fabric edges and glue point safety

Reliable suppliers provide inspection photos and testing reports for full transparency.

🎀 Step 6: Forecasting and Seasonal Planning

Hair bows often follow seasonal fashion trends. Work with your manufacturer at least 60–90 days before each major season to ensure on-time delivery. Trend-forward brands often order neutral colors for year-round sales and bold shades for holiday or school seasons.

🎀 Step 7: Building Long-Term Partnerships

Long-term collaboration reduces costs and improves consistency. When you stay with the same factory, they retain your molds, material records, and previous color codes—saving both time and sampling fees.

💡 Conclusion

Launching a private label hair bow collection is not just about design — it’s about creating a reliable and repeatable supply chain. Partnering with experienced Hair Accessories Manufacturers and specialized Hair Bow Manufacturers ensures your bows meet the expectations of global retail buyers in quality, packaging, and delivery.